Underwater fishing techniques

Speargun maintenance: treat it well to use it better

Speargun maintenance: treat it well to use it better

Anyone who has ever handled a crossbow knows perfectly well that after every trip at sea the equipment must be washed with plenty of fresh water: it is the first rule for whom spearfishing, and it applies in particular to those who use this type of rifle.

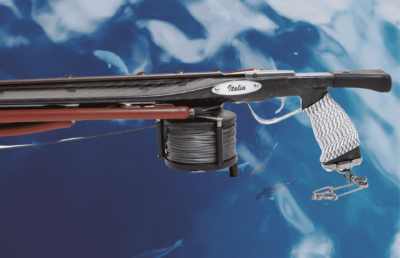

Spearguns are small mechanical masterpieces that use a very limited number of components in a simple yet effective mechanism, which allows powerful and very precise shots without requiring a maintenance particularly expensive.

Even in the most sophisticated speargun, there are few good rules to follow in order to always have perfect equipment and they are quite simple to put into practice.

Speargun maintenance: rubber wear

The speargun system derives directly from that of the ballista, an ancient siege weapon similar to a large crossbow (arbalète in French) invented by the ancient Greeks: like a crossbow, the arbalete exploits the propulsion of a rubber band to fire a steel rod that runs along the barrel of the rifle.

Whether it's wood or carbon, the speargun requires one minimal maintenance thanks to the simplicity of its mechanism: the only part subject to significant wear, which therefore must be treated with the utmost attention, is precisely the rubber.

- rubber bands, on which the power of the shots and the performance of the speargun directly depend, tend to lose elasticity over time and can become unusable even after a few weeks of stalling, if for example they remain in contact with salt water or are stored in a not very careful.

Speargun: commercial, roller or demultiplied?

This applies to cheap commercial spearguns just as much as it does to rubber band rifles traditional (or roller) and for demultiplied spearguns, which use a system of pulleys to store more energy and increase the ratio between the force exerted and the power of the throw.

However, maintenance can be significantly different, based on the type of speargun you have available: commercial and traditional spearguns, in fact, base their functioning precisely on the stretch of the elastic, which is hooked to the muzzle and pulled as far as possible, so the rubbers of these tools are inevitably subjected to a certain level of stress.

It is no coincidence that the producers of the highest level roller spearguns have focused on the tire quality: the right reactivity of the material, in the case of rollers, is one of the key factors for prolong the life of the rubber bands.

In demultiplied systems, on the contrary, the tires are subjected to stretching factors very low, which "saves" them from the preload stress that can afflict the rubbers of a commercial speargun. It goes without saying that maintenance will be, at least to some extent, simplified.

Speargun: the three golden rules

La ease of maintenance it is certainly one of the best qualities of the speargun: if it is true that it is enough to change the rubber to have a speargun like new, it must also be considered that the mechanical parts and parts subject to wear are really limited and can be treated well without great effort .

Obviously each speargun has its own specific characteristics, so the first thing to do if in doubt is to consult the instructions provided by the manufacturer at the time of purchase. However, there are some good habits that apply to all spearguns, and some mistakes to avoid carefully:

- always wash the speargun with plenty of fresh water after each fishing trip: salt is the first enemy of speargun rubbers and mechanics. In addition to the galvanic corrosion caused by sea water, the salt contained in it can generate dangerous friction phenomena in the release mechanism;

- never leave the speargun directly exposed to the sun o in places with temperatures above 40°: heat and sunlight seriously damage the rubber, causing phenomena such as cracking of the elastics and their dissolution (the famous "sweating" elastics);

- if you leave the equipment for more than a few days, store the speargun in a place free from sudden changes in temperature (preferably in a protective bag) paying particular attention to the elastic bands, which must be stored away from the air and in such a way as not to have weights on them, possibly on a shelf or on a surface dedicated to them.

Speargun maintenance: checking the tires is not enough

The first thing to do to always have a speargun at its maximum potential and up to the situation is a smooth control of the elastics: in fact, it may happen that the tire starts to lose momentum well before showing obvious signs of wear. Before each ride it is therefore good to check the degree of reactivity of the tires.

The second check to do concerns the release mechanism, the safety of the speargun depends on its proper functioning. Some fishermen have the habit of lubricating this mechanism using silicone or specific products for marine use: this operation allows to reduce the friction with the release tooth, and always have optimal performance.

Who uses a nylon line, in particular, will also have to devote some time to the regular complete unwinding of the thread: unlike the Dyneema braidIn fact, nylon memorizes the shape in which it is left and over time it becomes more prone to forming those coils or "wigs" of curled thread that have always made cannisters and divers damned.

Also 'it should be checked regularly: in addition to sharpening the point, which can be done with an iron file or with the help of a grindstone, it is advisable to check that the fins they open without difficulty and that they adhere well to the rod: from auction profile in fact, most of the hydrodynamic characteristics of the throw depend, so much so that a too protruding fin can act as a rudder and even deflect a cast.